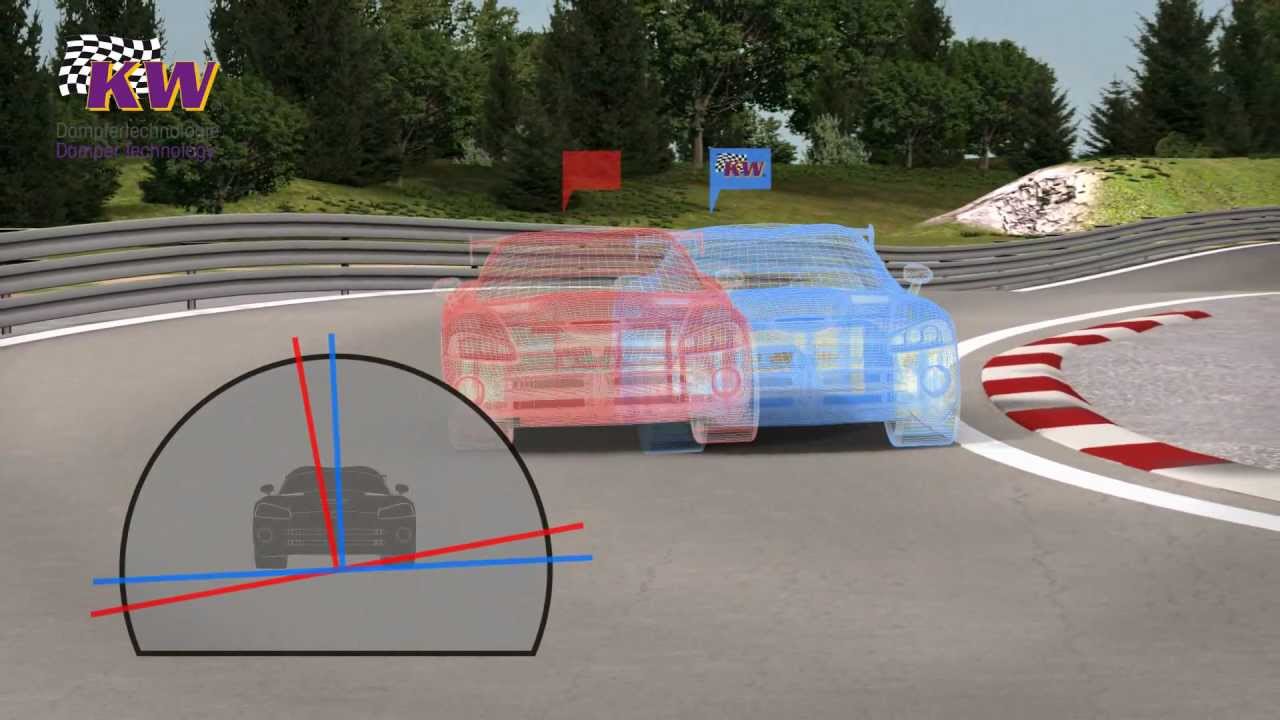

KW damping and valve technology, 2-way

KWήΒχήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΔΗήΓψήΔΟήΔφήΓ╕ήΔ╝ήΒψήΑΒί╣Ζί║ΔήΒΕήΓλήΔΩήΔςήΓ▒ήΔ╝ήΓ╖ήΔπήΔ│ήΒρήΓτήΔΗήΓ┤ήΔςήΔ╝ήΒτϊ╜┐ήΓΠήΓΝήΒοήΒΕήΒ╛ήΒβήΑΓ

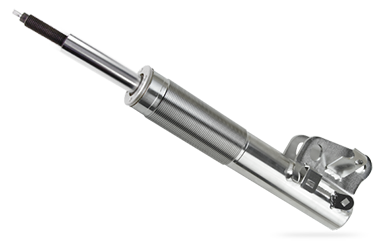

ήΔΑήΔ│ήΔΣήΔ╝ήΒχίθ║όευέΑΥήΓ╖ήΔπήΔΔήΓψήΓλήΔΨήΓ╜ήΔ╝ήΔΡήΔ╝ήΒχόσθϋΔ╜

ήΓ╖ήΔπήΔΔήΓψήΓλήΔΨήΓ╜ήΔ╝ήΔΡήΔ╝ήΒχϊ╗Χϊ║ΜήΒψήΑΒϋ╗Λϋ╝ςήΑΒϋ╗Λϋ╗╕ήΑΒήΒΛήΓΙήΒ│ήΔεήΔΘήΓμήΒτήΓΙήΒμήΒοί╝ΧήΒΞϋ╡╖ήΒΥήΒΧήΓΝήΓΜόΝψίΜΧήΓΤόΛΣήΒΙήΓΜήΒΥήΒρήΒπήΒβήΑΓ ίΘ╣ίΘ╕ήΓΤϊ╣ΩήΓΛϋ╢ΛήΒΙήΓΜήΒρήΑΒύβ║ύΦθήΒΩήΒθϋκζόΤΔήΓΕόΝψίΜΧήΒΝήΓ╡ήΓ╣ήΔγήΔ│ήΓ╖ήΔπήΔ│ήΒτίΡ╕ίΠΟήΒΧήΓΝήΒ╛ήΒβήΑΓ

ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒψί╕╕ήΒτϊ╝╕ήΒ│ήΓΙήΒΗήΒρήΒΩήΒοήΒΕήΒ╛ήΒβήΑΓϋΥΕήΒΙήΓΚήΓΝήΒθήΓρήΔΞήΔτήΓχήΔ╝ήΓΤϋπμόΦ╛ήΒΩήΒθήΒΕύΛ╢όΖΜήΒπήΒβήΑΓ ήΒΥήΓΝήΓΚήΒχίΠΞί╛σήΒπήΑΒόΝψίΜΧήΒΝύβ║ύΦθήΒΩήΒ╛ήΒβήΑΓ ήΒΥήΓΝήΓΚήΒχίΜΧήΒΞήΒψήΑΒήΔΦήΓ╣ήΔΙήΔ│ήΔφήΔΔήΔΚήΓΤϊ╗ΜήΒΩήΒοήΓ╖ήΔπήΔΔήΓψήΓλήΔΨήΓ╜ήΔ╝ήΔΡήΔ╝ήΒτϊ╝ζώΒΦήΒΧήΓΝήΒ╛ήΒβήΑΓ ήΒΥήΒΥήΒπήΒψώΒΜίΜΧήΓρήΔΞήΔτήΓχήΔ╝ήΒψήΑΒήΓ╖ήΔπήΔΔήΓψήΓλήΔΨήΓ╜ήΔ╝ήΔΡήΔ╝ήΔΡήΔτήΔΨήΒχό▓╣ίεπόΛ╡όΛΩήΒτήΓΙήΒμήΒούΗ▒ήΒτίνΚόΠδήΒΧήΓΝήΑΒόΝψίΜΧήΓΤόεΑί░ΠώβΡήΒτόΛΣήΒΙήΒ╛ήΒβήΑΓ

- ώΑμύ╢γήΒβήΓΜόΝψίΜΧ

- ίΛιώΑθήΒ╛ήΒθήΒψήΔΨήΔυήΔ╝ήΓφήΔ│ήΓ░όβΓήΒχόΝβίΜΧ

- ϋ┐╜ί╛ΥόΑπϋΔ╜

- ήΓ│ήΔ╝ήΔΛήΔςήΔ│ήΓ░

ϋ╗Λϊ╕κήΒτϊ╜┐ύΦρήΒΧήΓΝήΓΜήΓ╖ήΔπήΔΔήΓψήΓλήΔΨήΓ╜ήΔ╝ήΔΡήΔ╝ήΒψήΑΒώΑγί╕╕ήΑΒήΔΕήΓνήΔ│ήΔΒήΔξήΔ╝ήΔΨήΔΑήΔ│ήΔΣήΔ╝ήΒ╛ήΒθήΒψήΔλήΔΟήΔΒήΔξήΔ╝ήΔΨήΔΑήΔ│ήΔΣήΔ╝ήΒπήΒβήΑΓ ήΔΦήΓ╣ήΔΙήΔ│ήΒψήΑΒήΒΥήΓΝήΓΚήΒχήΔΑήΔ│ήΔΣήΔ╝ήΓ┐ήΓνήΔΩήΒπήΓ╖ήΔςήΔ│ήΔΑήΔ╝ίΗΖήΓΤύπ╗ίΜΧήΒΩήΒ╛ήΒβήΑΓ ήΔΦήΓ╣ήΔΙήΔ│ήΒψήΓςήΓνήΔτήΓΤήΔΡήΔτήΔΨήΒτόΛ╝ήΒΩϋ╛╝ήΒ┐ήΑΒήΒΧήΒ╛ήΒΨήΒ╛ήΒςύσ┤ήΓΕήΓςήΔςήΔΧήΓμήΓ╣ήΓΤώΑγήΒμήΒοήΓςήΓνήΔτήΒχό╡ΒήΓΝήΒτόΛ╡όΛΩήΓΤύβ║ύΦθήΒΧήΒδήΒοό╕δϋκ░ίΛδήΓΤύΦθήΒαήΒΧήΒδήΒ╛ήΒβήΑΓ

ήΔΕήΓνήΔ│ήΔΒήΔξήΔ╝ήΔΨήΒπήΒψήΔςήΔΡήΓοήΔ│ήΔΚϊ╕φήΑΒήΓςήΓνήΔτήΒψήΓλήΓοήΓ┐ήΔ╝ήΔΒήΔξήΔ╝ήΔΨήΒΜήΓΚήΓνήΔ│ήΔΛήΔ╝ήΔΒήΔξήΔ╝ήΔΨήΒτόΙ╗ήΓΛήΒ╛ήΒβήΑΓ ήΓςήΓνήΔτήΒψήΑΒήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΡήΔτήΔΨήΒτίΛιήΒΙήΒοήΑΒήΔΦήΓ╣ήΔΙήΔ│ήΔφήΔΔήΔΚήΒτήΒΓήΓΜήΔςήΔΡήΓοήΔ│ήΔΚήΔΡήΔτήΔΨήΒτήΓΓό╡ΒήΓΝήΑΒήΔΦήΓ╣ήΔΙήΔ│ήΔΠήΓοήΓ╕ήΔ│ήΓ░ήΒτίΖξήΓΛήΒ╛ήΒβήΑΓ

KWήΔΕήΓνήΔ│ήΔΒήΔξήΔ╝ήΔΨήΓ╖ήΔπήΔΔήΓψήΓλήΔΨήΓ╜ήΔ╝ήΔΡήΔ╝ήΒχόσθϋΔ╜

ϋ╡░ϋκΝϊ╕φήΒτήΓ╡ήΓ╣ήΔγήΔ│ήΓ╖ήΔπήΔ│ήΒΝύ╕χήΓΑήΒρήΑΒήΔΦήΓ╣ήΔΙήΔ│ήΔφήΔΔήΔΚήΒΝίΖξήΓΛϋ╛╝ήΓΑήΒΥήΒρήΒτήΓΙήΒμήΒοήΓΠήΒγήΒΜήΒτίεπίΛδήΒχόΟδήΒΜήΒμήΒοήΒΕήΓΜήΓςήΓνήΔτήΒΝύπ╗ίΜΧήΒΩήΒ╛ήΒβήΑΓ ύ╕χήΒ┐ίΒ┤ήΒχό╡ΒώΑθήΓΤίΙ╢ί╛κήΒβήΓΜήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΡήΔτήΔΨήΒΜήΓΚήΓλήΓοήΓ┐ήΔ╝ήΔΒήΔξήΔ╝ήΔΨήΒτό╡ΒήΓΝϋ╛╝ήΒ┐ήΒ╛ήΒβήΑΓ

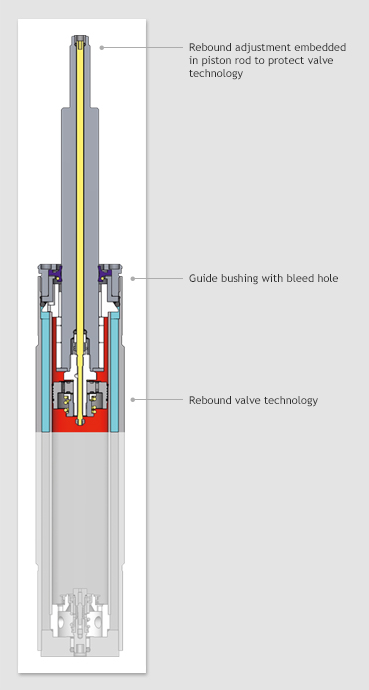

Rebound adjustment

ϊ╝╕ύ╕χύΜυύτΜήΒΩήΒθήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░Ύ╝Ιϊ╝╕ήΒ│ίΒ┤ό╕δϋκ░ίΛδΎ╝Κϋς┐όΧ┤

ϋς┐όΧ┤ήΔΟήΔΨήΓΤί╖χήΒΩϋ╛╝ήΒ┐ήΔςήΔΡήΓοήΔ│ήΔΚϋς┐όΧ┤

ϋς┐όΧ┤ήΔΑήΓνήΔνήΔτϊ╗αήΒΞήΔςήΔΡήΓοήΔ│ήΔΚϋς┐όΧ┤

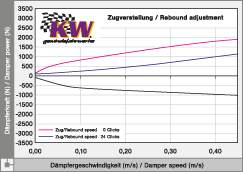

16 Clicks – Best perfomance and easy adjustment

KW Version 2,3ήΑΒKW ClubsportήΒΛήΓΙήΒ│KW Street ComfortήΒψήΑΒ16ήΓψήΔςήΔΔήΓψήΒχήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ϋς┐όΧ┤ήΒΝίΠψϋΔ╜ήΒπήΒβήΑΓ

ήΔςήΔΡήΓοήΔ│ήΔΚϋς┐όΧ┤ήΒψήΑΒήΓΙήΓΛήΔΑήΓνήΔΛήΔθήΔΔήΓψήΒςύΚ╣όΑπήΓΤίΘ║ήΒΩήΒθήΓΛήΑΒήΓ┐ήΓνήΔνήΒχίνΚόδ┤ήΓΕϋ╡░ϋκΝήΓ╣ήΔΗήΔ╝ήΓ╕ήΒτίΡΙήΓΠήΒδήΒοήΔβήΓ╣ήΔΙήΒςϋς┐όΧ┤ήΓΤϋκΝήΒΗήΒΥήΒρήΒΝίΠψϋΔ╜ήΒπήΒβήΑΓ

Version2ϊ╗ξϊ╕ΛήΒχήΓ╡ήΓ╣ήΔγήΔ│ήΓ╖ήΔπήΔ│ήΒψήΑΒϋ╗Λώταϋς┐όΧ┤όσθϋΔ╜ϊ╗ξϊ╕ΛήΒχήΓΓήΒχήΓΤήΔοήΔ╝ήΓ╢ήΔ╝ήΒτόΠΡϊ╛δήΒΩήΒ╛ήΒβήΑΓ

ϋς┐όΧ┤ίΠψϋΔ╜ήΒςήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░όσθϋΔ╜ήΒτήΓΙήΓΛήΑΒήΔοήΔ╝ήΓ╢ήΔ╝ήΒψήΓΙήΓΛήΓ╣ήΔζήΔ╝ήΔΗήΓμήΒπήΓΙήΓΛήΓ┐ήΓνήΔΙήΒςήΔΠήΔ│ήΔΚήΔςήΔ│ήΓ░ύΚ╣όΑπήΑΒήΒ╛ήΒθήΒψήΓΙήΓΛί┐τώΒσήΒςϋς┐όΧ┤ήΓΤϋκΝήΒΗήΒΥήΒρήΒΝήΒπήΒΞήΒ╛ήΒβήΑΓ

Technical details of adjustable rebound damping

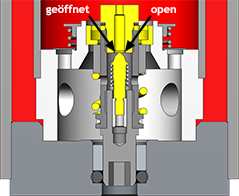

ό╕δϋκ░ίΛδήΒΝήΔΠήΔ╝ήΔΚήΒςόβΓήΒχήΔςήΔΡήΓοήΔ│ήΔΚήΓ╣ήΔΙήΔφήΔ╝ήΓψϊ╕φήΒχήΓςήΓνήΔτήΒχό╡ΒήΓΝ

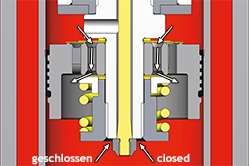

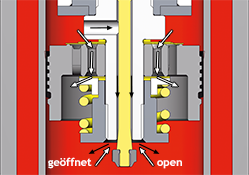

ήΓψήΔςήΔΔήΓψήΒπώΨΜώΨΚήΒβήΓΜώΔρίΙΗήΒΝώΨΚήΒαήΒοήΒΕήΓΜύΛ╢όΖΜήΒπήΒβήΑΓ όεΑήΓΓί╝╖ήΒΕήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓΤύβ║ύΦθήΒΧήΒδήΒ╛ήΒβήΑΓ

ύ╡ΡόηεΎ╝γίΞαήΒτήΔΠήΔ╝ήΔΚήΒτήΒςήΓΜήΒχήΒπήΒψήΒςήΒΠήΑΒήΒΩήΒμήΒΜήΓΛήΒρήΔςήΔΡήΓοήΔ│ήΔΚήΒΩήΒςήΒΝήΓΚήΑΒήΔφήΔ╝ήΔτήΒΛήΓΙήΒ│ήΔΦήΔΔήΔΒήΔ│ήΓ░ήΔλήΔ╝ήΓ╖ήΔπήΔ│ήΒΝίδηώΒ┐ήΒΧήΓΝήΒ╛ήΒβήΑΓ

ό╕δϋκ░ίΛδήΒΝήΓ╜ήΔΧήΔΙήΒςόβΓήΒχήΔςήΔΡήΓοήΔ│ήΔΚήΓ╣ήΔΙήΔφήΔ╝ήΓψϊ╕φήΒχήΓςήΓνήΔτήΒχό╡ΒήΓΝ

ήΓψήΔςήΔΔήΓψήΒπώΨΜώΨΚήΒβήΓΜώΔρίΙΗήΒΝώΨΜήΒΕήΒοήΒΕήΓΜύΛ╢όΖΜήΒπήΒβήΑΓ όεΑήΓΓί╝▒ήΒΕήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓΤύβ║ύΦθήΒΧήΒδήΒ╛ήΒβήΑΓ

ύ╡ΡόηεΎ╝γήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΒΝϊ╜ΟήΒΕήΒ╗ήΒσήΑΒί┐τώΒσήΒςώΒΜϋ╗λήΒΝίΠψϋΔ╜ήΒτήΒςήΓΛήΒ╛ήΒβήΑΓ

ήΔςήΔΡήΓοήΔ│ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓΤϋς┐όΧ┤ήΒβήΓΜήΒρήΒΞήΒχήΑΒήΔΑήΔ│ήΔΣήΔ╝ήΓ╣ήΔΦήΔ╝ήΔΚΎ╝Ιm / sΎ╝ΚήΒΜήΓΚό╕δϋκ░ίΛδΎ╝ΙNΎ╝ΚήΒ╕ήΒχώΨλϊ┐ΓήΒχήΓ░ήΔσήΔΧήΓμήΔΔήΓψήΑΓ

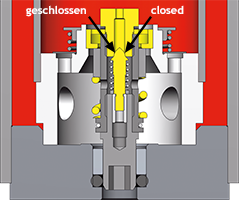

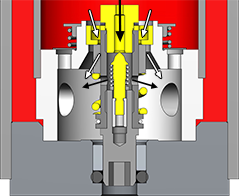

Compression adjustment

ϊ╝╕ύ╕χύΜυύτΜήΒΩήΒθήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░Ύ╝Ιύ╕χήΒ┐ίΒ┤ό╕δϋκ░ίΛδΎ╝Κϋς┐όΧ┤

ϋς┐όΧ┤ήΔΟήΔΨήΒτήΓΙήΓΜήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ϋς┐όΧ┤

ώΨΜίΠμώΔρήΒΜήΓΚήΓλήΓψήΓ╗ήΓ╣ήΒπήΒΞήΓΜ4ύσ┤ήΓλήΓ╕ήΔμήΓ╣ήΓ┐ήΔ╝ήΒτήΓΙήΓΜήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ϋς┐όΧ┤

ήΔΑήΔ│ήΔΣήΔ╝ήΒχϊ╕ΜώΔρήΒτήΒΓήΓΜϋς┐όΧ┤ήΔΑήΓνήΔνήΔτήΓΤίδηήΒβήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ϋς┐όΧ┤

ήΔΑήΔ│ήΔΣήΔ╝ήΒρϊ╕Αϊ╜ΥίηΜήΒχϋς┐όΧ┤ήΔΑήΓνήΔνήΔτήΒτήΓΙήΓΜήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ϋς┐όΧ┤

12ήΓψήΔςήΔΔήΓψϋς┐όΧ┤ίΠψϋΔ╜ήΒςήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░

KW Version 3ήΒΛήΓΙήΒ│KW Clubsport 2wayήΒψήΑΒϋ╗Λϊ╕κήΒχί╣Ζί║ΔήΒΕήΔΑήΔ│ήΔΦήΔ│ήΓ░ϋς┐όΧ┤ήΓΤώΘΞϋοΨήΒβήΓΜήΔΣήΔΧήΓσήΔ╝ήΔηήΔ│ήΓ╣ί┐ΩίΡΣήΒχύΡΗόΔ│ύγΕήΒςήΓ╖ήΓ╣ήΔΗήΔιήΒπήΒβήΑΓ

ύΜυύτΜήΒΩήΒθήΔςήΔΡήΓοήΔ│ήΔΚήΒΛήΓΙήΒ│ήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΒτήΓΙήΓΛήΑΒί╣Ζί║ΔήΒΕήΔΑήΔ│ήΔΣήΔ╝ήΔΒήΔξήΔ╝ήΔΜήΔ│ήΓ░ήΒΝίΠψϋΔ╜ήΒτήΒςήΓΛήΒ╛ήΒβήΑΓ ήΒΥήΓΝήΒτήΓΙήΓΛήΑΒήΓ┐ήΔ╝ήΔ│ήΓνήΔ│ύΚ╣όΑπήΑΒίχΚίχγόΑπήΑΒήΓ░ήΔςήΔΔήΔΩήΑΒήΒΛήΓΙήΒ│ϋ╗Λϊ╕κήΒχώβΡύΧΝήΒπήΒχήΔΠήΔ│ήΔΚήΔςήΔ│ήΓ░ήΑΒώΒΜίΜΧόΑπϋΔ╜ήΒτύδ┤όΟξί╜▒ώθ┐ήΓΤϊ╕ΟήΒΙήΓΜήΒΥήΒρήΒΝήΒπήΒΞήΒ╛ήΒβήΑΓ

ύΜυύτΜήΒΩήΒθήΔςήΔΡήΓοήΔ│ήΔΚήΒρήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΒχήΒθήΓΒήΒχύΚ╣ϋρ▒ίΠΨί╛Ωό╕ΙήΒ┐ήΒχKWήΔΡήΔτήΔΨήΔΗήΓψήΔΟήΔφήΓ╕ήΔ╝ήΒτήΓΙήΓΛήΑΒήΔοήΔ╝ήΓ╢ήΔ╝ήΒψKWήΔΑήΔ│ήΔΣήΔ╝ήΒχήΓ╗ήΔΔήΔΙήΓλήΔΔήΔΩήΒΝϋΘςύΦ▒ϋΘςίερήΒπήΒβήΑΓ

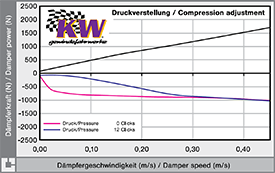

Technology of compression damping in detail

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the compression damping.

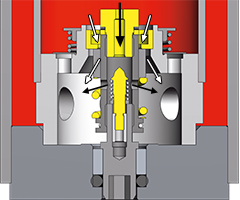

ήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΡήΔτήΔΨήΒΝώΨΚήΒαήΒοήΒΕήΓΜόβΓήΒχήΓςήΓνήΔτήΒχό╡ΒήΓΝ

ίδ│1Ύ╝γ

ήΔΩήΔςήΔφήΔ╝ήΔΚήΒΝόΟδήΒΜήΒμήΒθήΔΡήΓνήΔΣήΓ╣ήΔΡήΔτήΔΨήΒψήΑΒήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΓ╣ήΔΙήΔφήΔ╝ήΓψήΒΝίπΜήΒ╛ήΓΜίΚΞήΒψώΨΚήΒαήΒθύΛ╢όΖΜήΒπήΒβήΑΓ

ίδ│2:

ήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΓ╣ήΔΙήΔφήΔ╝ήΓψήΒΝίπΜήΒ╛ήΓΜήΒρήΑΒώΨΚήΒαήΒοήΒΕήΓΜήΔΜήΔ╝ήΔΚήΔτήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒΝίεπίΛδήΒτήΓΙήΒμήΒού╕χήΓΥήΒπήΒΕήΒΞήΒ╛ήΒβήΑΓ

ήΔΦήΓ╣ήΔΙήΔ│ήΓ╣ήΔΦήΔ╝ήΔΚήΒΝϊ╜ΟήΒΕήΒρήΒΞΎ╝Ιώ╗ΤήΒΕύθλίΞ░Ύ╝ΚήΑΒήΓςήΓνήΔτήΒΝήΔΡήΓνήΔΣήΓ╣ήΔΡήΔτήΔΨήΓΤό╡ΒήΓΝήΒοήΒΕήΒ╛ήΒβήΑΓ

ύβ╜ήΒΕύθλίΞ░ήΒψήΑΒήΔΦήΓ╣ήΔΙήΔ│ήΓ╣ήΔΦήΔ╝ήΔΚήΒΝώΑθήΒΕήΒρήΒΞήΒτήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒΝίεπύ╕χήΒΧήΓΝήΓςήΓνήΔτήΒΝό╡ΒήΓΝήΒ╛ήΒβήΑΓ ώΨΚήΒαήΒθήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΡήΔτήΔΨήΒψήΑΒήΔφήΔ╝ήΓ╣ήΔΦήΔ╝ήΔΚήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░Ύ╝Ιϊ╜ΟώΑθίεπύ╕χό╕δϋκ░ίΛδΎ╝ΚήΓΤϋς┐όΧ┤ήΒΩήΒ╛ήΒβήΑΓ

ύ╡Ρόηε:

ήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓΤί╝╖ήΒΠήΒβήΓΜήΒΥήΒρήΒπήΑΒήΓ│ήΔ╝ήΔΛήΔςήΔ│ήΓ░όβΓήΒςήΒσήΓ░ήΔςήΔΔήΔΩίΛδήΒχώβΡύΧΝήΒΝώταήΒΠήΒςήΓΛήΒ╛ήΒβήΑΓ

ήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΡήΔτήΔΨήΒΝώΨΜήΒΕήΒοήΒΕήΓΜόβΓήΒχήΓςήΓνήΔτήΒχό╡ΒήΓΝ

ίδ│1:

ήΔΩήΔςήΔφήΔ╝ήΔΚήΒΝόΟδήΒΜήΒμήΒθήΔΡήΓνήΔΣήΓ╣ήΔΡήΔτήΔΨήΒψήΑΒήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΓ╣ήΔΙήΔφήΔ╝ήΓψήΒΝίπΜήΒ╛ήΓΜίΚΞήΒΜήΓΚώΨΜήΒΕήΒθύΛ╢όΖΜήΒπήΒβήΑΓ

ίδ│2:

ήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΓ╣ήΔΙήΔφήΔ╝ήΓψήΒΝίπΜήΒ╛ήΓΜήΒρήΑΒώΨΚήΒαήΒοήΒΕήΓΜήΔΜήΔ╝ήΔΚήΔτήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒΝίεπίΛδήΒτήΓΙήΒμήΒού╕χήΓΥήΒπήΒΕήΒΞήΒ╛ήΒβήΑΓ

ήΔΦήΓ╣ήΔΙήΔ│ήΓ╣ήΔΦήΔ╝ήΔΚήΒΝώΒΖήΒΕίι┤ίΡΙΎ╝Ιώ╗ΤήΒΕύθλίΞ░Ύ╝ΚήΑΒήΓςήΓνήΔτήΒΝήΔΡήΓνήΔΣήΓ╣ήΔΡήΔτήΔΨήΓΤό╡ΒήΓΝήΒοήΒΕήΒ╛ήΒβήΑΓ

ήΔΠήΓνήΓ╣ήΔΦήΔ╝ήΔΚήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░(ώταώΑθίεπύ╕χό╕δϋκ░ίΛδ)Ύ╝Ιύβ╜ήΒΕύθλίΞ░Ύ╝ΚήΒψήΑΒϋς┐όΧ┤ήΓψήΔςήΔΔήΓψήΒπίνΚίΝΨήΒχήΒςήΒΕήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒχήΔΩήΔςήΔφήΔ╝ήΔΚήΒτήΓΙήΒμήΒοό▒║ήΒ╛ήΓΛήΒ╛ήΒβήΑΓ ώΨΜήΒΕήΒθήΔΡήΓνήΔΣήΓ╣ήΔΡήΔτήΔΨήΒψήΑΒήΔφήΔ╝ήΓ╣ήΔΦήΔ╝ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░(ϊ╜ΟώΑθό╕δϋκ░ίΛδ)ήΒπήΓ│ήΔ│ήΔΩήΔυήΔΔήΓ╖ήΔπήΔ│ήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓ░ήΔσήΔΧήΓΤύΦθόΙΡήΒΩήΒ╛ήΒβήΑΓ

ύ╡Ρόηε:

ήΒΥήΒχήΔΗήΓψήΔΟήΔφήΓ╕ήΔ╝ήΒψήΔφήΔ╝ήΓ╣ήΔΦήΔ╝ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓΤϋς┐όΧ┤ήΒΩήΑΒϊ╕Αϋ▓τήΒΩήΒθήΔΠήΓνήΓ╣ήΔΦήΔ╝ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΓΤίΠψϋΔ╜ήΒτήΒΩήΒ╛ήΒβήΑΓ ήΔΠήΓνήΓ╣ήΔΦήΔ╝ήΔΚήΔΑήΔ│ήΔΦήΔ│ήΓ░ήΒψήΔΡήΔτήΔΨήΒχώΨΜώΨΚ(ϋς┐όΧ┤ήΓψήΔςήΔΔήΓψ)ήΒτί╜▒ώθ┐ήΒΧήΓΝήΒ╛ήΒδήΓΥήΑΓ

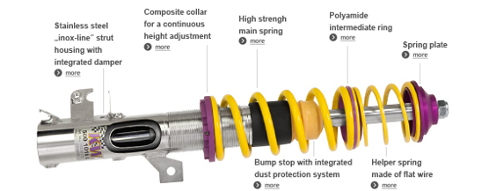

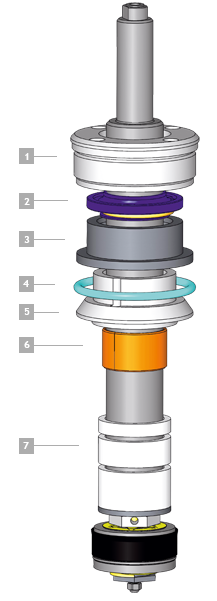

KWήΒχήΔΦήΓ╣ήΔΙήΔ│ήΔφήΔΔήΔΚήΒΛήΓΙήΒ│ήΓ╖ήΔ╝ήΔςήΔ│ήΓ░

- ώταί╝╡ίΛδήΓλήΔτήΔθήΔΛήΔΔήΔΙ

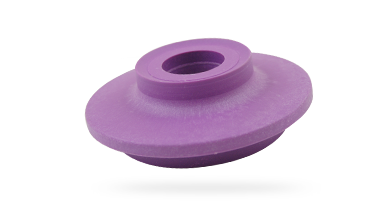

- ύΚ╣όχΛNBRήΓ╖ήΔ╝ήΔςήΔ│ήΓ░

- ήΓψήΔσήΔ│ήΔΦήΔ│ήΓ░ήΓ╣ήΔςήΔ╝ήΔΨ

- ϋΑΡύΗ▒ήΔΡήΓνήΔΙήΔ│ϋμ╜OήΔςήΔ│ήΓ░

- ήΔΨήΔςήΔ╝ήΔΚήΔδήΔ╝ήΔτϊ╗αήΒΞήΓυήΓνήΔΚήΔΨήΔΔήΓ╖ήΔξ

- ύΚ╣όχΛήΓ│ήΔ╝ήΔΗήΓμήΔ│ήΓ░ήΒΧήΓΝήΒθDUήΔΩήΔυήΔ╝ήΔ│ήΔβήΓλήΔςήΔ│ήΓ░

- ήΔςήΔΡήΓοήΔ│ήΔΚήΓ╣ήΔγήΔ╝ήΓ╡ήΔ╝

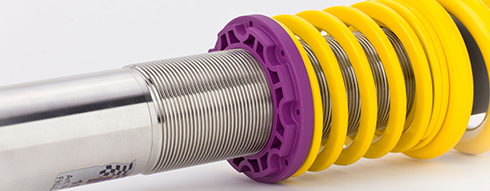

KWήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔΩήΔυήΔ╝ήΔΙήΒψήΑΒήΔαήΔτήΔΣήΔ╝ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓΕήΔκήΓνήΔ│ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓΤόφμήΒΩήΒΕϊ╜Ξύ╜χήΒτϊ┐ζόΝΒήΒβήΓΜήΒιήΒΣήΒπήΒςήΒΠήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒχόΝψίΜΧήΔΟήΓνήΓ║ήΓΤόεΑί░ΠώβΡήΒτόΛΣήΒΙήΒ╛ήΒβήΑΓ ϋ╗Λϊ╕κήΒχήΓ┐ήΓνήΔΩήΒρύΦρώΑΦήΒτί┐εήΒαήΒοήΑΒKWήΒψώταίΥΒϋ│ςήΒχήΓλήΔτήΔθήΔΜήΓοήΔιίΡΙώΘΣήΒ╛ήΒθήΒψήΔζήΔςήΓλήΔθήΔΚϋνΘίΡΙόρ╣ϋΕΓήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔΩήΔυήΔ╝ήΔΙήΓΤϋμ╜ώΑιήΒΩήΒοήΒΕήΒ╛ήΒβήΑΓ ήΓλήΔτήΔθήΔΜήΓοήΔιϋμ╜ήΒπήΓΓώΝΗήΒ│ήΒτήΒΠήΒΕϋνΘίΡΙόζΡϋμ╜ήΒπήΓΓήΑΒώζηί╕╕ήΒτϋ╗╜ώΘΠήΒπήΒβήΑΓ

ήΔαήΔτήΔΣήΔ╝ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒψήΑΒώταίΥΒϋ│ςήΒχήΓψήΔφήΔιήΓ╖ήΔςήΓ│ήΔ│ήΓ╣ήΔΒήΔ╝ήΔτήΒπήΒπήΒΞήΒοήΒΛήΓΛήΑΒήΔΧήΔσήΔΔήΔΙήΒςϋρφϋρΙήΒτήΒςήΒμήΒοήΒΕήΒ╛ήΒβήΑΓ ήΓ╣ήΔΩήΔςήΔ│ήΔΙήΓ╖ήΔ╝ήΔΙήΓΤϊ╕ΜήΒΤήΒοϋ╗ΛώταήΓΤϊ╕ΜήΒΤήΒοήΓΓήΑΒήΔκήΓνήΔ│ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒχόΑπϋΔ╜ήΓΤϊ┐ζήΒκήΒ╛ήΒβήΑΓ ϋ╗Λϊ╕κήΒχώΘΞώΘΠήΒΝήΔαήΔτήΔΣήΔ╝ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒτόΟδήΒΜήΓΜήΒρήΒβήΒΡήΒτύ╕χήΓΥήΒπήΔΨήΔφήΔΔήΓψήΒχήΓΙήΒΗήΒτήΒςήΓΛήΑΒήΔκήΓνήΔ│ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒχόΑπϋΔ╜ήΒτί╜▒ώθ┐ήΓΤίΠΛήΒ╝ήΒΩήΒ╛ήΒδήΓΥήΑΓ

KWήΒΝϊ╜┐ύΦρήΒβήΓΜϋ╗╜ώΘΠήΒχήΔζήΔςήΓλήΔθήΔΚϋνΘίΡΙόρ╣ϋΕΓήΒπϊ╜εήΓΚήΓΝήΒθϊ╕φώΨΥήΔςήΔ│ήΓ░ήΒψήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓΤϊ┐ζόΝΒήΒβήΓΜήΒιήΒΣήΒπήΒςήΒΠήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒχόΝψίΜΧήΔΟήΓνήΓ║ήΓΤόεΑί░ΠώβΡήΒτόΛΣήΒΙήΒ╛ήΒβήΑΓ

ήΔΑήΓ╣ήΔΙήΓτήΔΡήΔ╝ήΒψήΑΒό░┤ήΓΕό▒γήΓΝήΒχύ▓ΤίφΡήΒΝήΔΦήΓ╣ήΔΙήΔ│ήΔφήΔΔήΔΚήΓ╖ήΔ╝ήΔτήΒτίΙ░ώΒΦήΒβήΓΜήΒχήΓΤώα▓ήΒΟήΒ╛ήΒβήΑΓ

ήΔΩήΔφήΓ░ήΔυήΔΔήΓ╖ήΔΨήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔυήΔ╝ήΔΙ

ήΔΩήΔφήΓ░ήΔυήΔΔήΓ╖ήΔΨήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒψύΧ░ήΒςήΓΜί╝╖ήΒΧήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ί╖╗ύ╖γήΒπόπΜόΙΡήΒΧήΓΝήΒ╛ήΒβήΑΓίΛδήΒΝϊ╜εύΦρήΒβήΓΜήΒρήΑΒί╝▒ήΒΕί╖╗ύ╖γήΒψόεΑίΙζήΒτίεπύ╕χήΒΧήΓΝήΑΒόυκήΒτί╝╖ήΒΕί╖╗ύ╖γήΒΝίεπύ╕χήΒΧήΓΝήΒ╛ήΒβήΑΓίΡΝήΒαίΛ╣όηεήΒψήΑΒϊ║ΤήΒΕήΒτώΘΞήΒφήΒοώΖΞύ╜χήΒΧήΓΝήΒθ2ήΒνήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓΤϊ╜┐ύΦρήΒβήΓΜήΒΥήΒρήΒπήΓΓί╛ΩήΓΚήΓΝήΒ╛ήΒβήΑΓ

ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔυήΔ╝ήΔΙήΒψήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒτϊ╜εύΦρήΒβήΓΜίΛδΎ╝ΙNΎ╝ΚήΒχώΘΠήΓΤύν║ήΒΩήΒ╛ήΒβήΑΓήΒΥήΓΝήΒτήΓΙήΓΛήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒψ1ήΔθήΔςύ╕χήΒ┐ήΒ╛ήΒβήΑΓύ░κίΞαήΒτϋςυόαΟήΒβήΓΜήΒρήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔυήΔ╝ήΔΙήΒΝώταήΒΕήΒ╗ήΒσήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒψύκυήΒΠήΒςήΓΛήΑΒήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓΤίεπύ╕χήΒβήΓΜήΒθήΓΒήΒτήΓΙήΓΛίνγήΒΠήΒχίΛδήΓΤήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒτϊ╜εύΦρήΒΧήΒδήΓΜί┐ΖϋοΒήΒΝήΒΓήΓΛήΒ╛ήΒβήΑΓ

ήΔςήΔΜήΓλήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔυήΔ╝ήΔΙ

ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒΝύδ┤ύ╖γύγΕήΒτί╖╗ήΒΜήΓΝήΒοήΒΕήΓΜίι┤ίΡΙήΑΒίΛδήΒψίεπύ╕χϋκΝύρΜήΒτόψΦϊ╛ΜήΒΩήΒ╛ήΒβήΑΓ ήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΔυήΔ╝ήΔΙήΒΝ70ήΔΜήΔξήΔ╝ήΔΙήΔ│Ύ╝ΙNΎ╝Κ/ mmήΒχίι┤ίΡΙήΑΒ70 NήΒΝήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΒτόΟδήΒΜήΓΛ1mmίεπύ╕χήΒΩήΒ╛ήΒβήΑΓ

KWήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓ╖ήΔ╝ήΔΙήΒψήΑΒήΓ╣ήΔΗήΔ│ήΔυήΓ╣ήΓ╣ήΔΒήΔ╝ήΔτήΓΤϋΑΡϊ╣ΖόΑπήΒχώταήΒΕήΔζήΔςήΓλήΔθήΔΚϋνΘίΡΙόρ╣ϋΕΓήΒπϋοΗήΓΠήΓΝήΒοϊ╜εήΓΚήΓΝήΒ╛ήΒβήΑΓ ήΔΨήΔυήΔ╝ήΓφήΔΑήΓ╣ήΔΙήΓΕύιΓύ▓ΤήΒςήΒσήΒΝήΔζήΔςήΓλήΔθήΔΚϋνΘίΡΙόρ╣ϋΕΓήΒτόΟξϋποήΒΩήΒοήΓΓϋΖΡώμθήΒςήΒσήΒψϋ╡╖ήΒΞήΒ╛ήΒδήΓΥήΑΓ ϊ┐ζϋφ╖ήΒΧήΓΝήΒοήΒΕήΒςήΒΕήΓλήΔτήΔθήΔΜήΓοήΔιήΓΕήΓ╣ήΔΒήΔ╝ήΔτήΒ╛ήΒθήΒψήΓ╣ήΔΗήΔ│ήΔυήΓ╣ήΓ╣ήΔΒήΔ╝ήΔτήΒχήΓ╣ήΔυήΔΔήΔΚήΒτώΘΣί▒ηήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓ╖ήΔ╝ήΔΙήΒΝύδ┤όΟξϋποήΓΝήΓΜήΒρήΑΒώΖ╕ίΝΨήΒΝύβ║ύΦθήΒΩίδ║ύζΑήΒΩήΒ╛ήΒβήΑΓ όεΑόΓςήΒχίι┤ίΡΙϋ╗ΛώταήΒχϋς┐όΧ┤ήΒΝήΒπήΒΞήΒςήΒΠήΒςήΓΛήΒ╛ήΒβήΑΓ INOX-LINEΎ╝ΙήΓ╣ήΔΗήΔ│ήΔυήΓ╣ήΓ╣ήΔΒήΔ╝ήΔτΎ╝ΚήΒχϋΑΡϊ╣ΖόΑπήΒχήΒΓήΓΜKWήΓ╡ήΓ╣ήΔγήΔ│ήΓ╖ήΔπήΔ│ήΒρήΑΒήΔζήΔςήΓλήΔθήΔΚϋνΘίΡΙόρ╣ϋΕΓήΒχήΓ╣ήΔΩήΔςήΔ│ήΓ░ήΓ╖ήΔ╝ήΔΙήΒχύ╡ΕήΒ┐ίΡΙήΓΠήΒδήΒψήΒΥήΓΝήΓΚήΒχήΔςήΓ╣ήΓψήΒΝήΒΓήΓΛήΒ╛ήΒδήΓΥήΑΓ

KWήΓ╡ήΓ╣ήΔγήΔ│ήΓ╖ήΔπήΔ│ήΒχήΓ▒ήΔ╝ήΓ╣ήΒψήΑΒώταίΥΒϋ│ςήΒςήΓ╣ήΔΗήΔ│ήΔυήΓ╣ήΓ╣ήΔΒήΔ╝ήΔτήΒπϊ╜εήΓΚήΓΝήΒοήΒΛήΓΛήΑΒϋΑΡϊ╣ΖόΑπήΓΕίψ┐ίΣ╜ήΒχώΧ╖ήΒΧήΒτίΕςήΓΝήΒ╛ήΒβήΑΓ ήΒβήΒ╣ήΒοήΒχό░Ωϋ▒κόζκϊ╗╢ήΒπήΑΒήΓ╣ήΔΗήΔ│ήΔυήΓ╣ήΓ╣ήΔΒήΔ╝ήΔτήΒχKWήΒψ100Ύ╝ΖϋΑΡϋΖΡώμθόΑπήΒΝήΒΓήΓΛήΑΒώΧ╖ίψ┐ίΣ╜ήΒπήΒβήΑΓ

KWήΒχίΠ░ί╜λήΓ╣ήΔυήΔΔήΔΚήΒρήΔζήΔςήΓλήΔθήΔΚϋνΘίΡΙόρ╣ϋΕΓήΒτήΓΙήΓΜϋ╗Λώταϋς┐όΧ┤όσθϋΔ╜ήΒψήΑΒώΧ╖όεθώΨΥϊ╜┐ύΦρήΒπήΒΞήΓΜήΓΙήΒΗήΒτϋρφϋρΙήΒΧήΓΝήΒοήΒΕήΒ╛ήΒβήΑΓ ίκσό░┤ίβ┤ώεπϋσοώρΥήΓΤίχθόΨ╜ήΒΩήΑΒKWήΒτώΖ╕ίΝΨήΒψήΒ╗ήΒρήΓΥήΒσϋοΜήΓΚήΓΝήΒ╛ήΒδήΓΥήΒπήΒΩήΒθήΑΓήΒΩήΒθήΒΝήΒμήΒοήΑΒόΧ░ί╣┤ί╛ΝήΒπήΓΓήΔκήΔ│ήΔΗήΔΛήΔ│ήΓ╣ήΓΤόΑιήΓΚήΒςήΒΣήΓΝήΒ░ϋ╗Λώταϋς┐όΧ┤ήΒψίχ╣όαΥήΒρήΒςήΓΛήΒ╛ήΒβήΑΓ